|

Part Design

Our almost 20 years experience in the injection molding industry has provided the Foxboro team with the knowledge to effectively design plastic components. We work closely with many of our customers engineering departments to design parts that will both optimize performance and minimize the tooling dollars required to produce the parts. We routinely assist our customers in the conversion of their components from metals, including aluminum, steel, brass, and stainless steel into plastics. Over the past 20 years this has proven to be a major cost savings to our customers.

Material Selection

A key factor in part design is material selection. Through our many contacts in the plastic compounding industry, Foxboro can suggest materials that will ensure high quality and cost effectiveness. These contacts also allow us the opportunity to provide uniquely formulated materials to best match the application. Foxboro has a computer-operated weigh scale blender in-house that allows us to transform standard resins into custom blended materials to fit the unique application of each part.

Currently we are utilizing anti-microbial additives for the food service industry and ultra violent light stabilizers for the HVAC industry. Our weigh scale blender also allows Foxboro to purchase materials in their natural color and add in precise amounts of color concentrates to create custom colors for our customers. The use of a computer controlled blending system allows us to ensure a high degree of accuracy in the formulation of the custom material from one production run to another.

This customer wanted their parts molded to match their own custom blue color. Our color concentrate supplier was able to develop a custom concentrate for the natural resin to match the custom blue. We now use our weigh scale blender to custom blend the natural resin and color concentrate to create the custom colored molded part.

|

Tool Design and Construction

Tool design and construction is not only crucial to the performance of plastic parts, but is also critical to achieving efficiency in production. Foxboro builds many of its own tools in our complete in-house machine shop. When the need arises we have external connections to outsource tool construction both domestically and internationally. |

Injection Molding

Our main area of expertise is injection molding; including insert molding and over molding. For a complete listing of our molding capabilities, click here. We welcome the opportunity to provide you with a quote for producing parts that are currently being molded on existing tooling elsewhere. What better way to ensure that your parts are being competitively molded?

In one application (black part, picture on left) our customer requires durable threads they can place a warranty on.

Therefore we designed a custom produced, threaded brass insert that we place into the mold prior to injecting the resin.

This results in stronger threads that will not separate from the part.

|

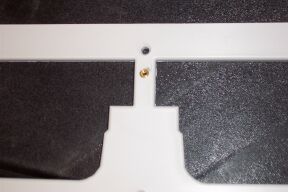

Another job (white part, picture on right) also requires durable threads and once again we insert mold the threaded brass inserts. |

|

Value Added Operations

Beyond part production, Foxboro has the capability to assist our customers in preparing their molded components for use in assembly lines or custom designed work cells. Whether it is the simple installation of a keeper nut, identification sticker or a more complex operation, Foxboro can help. These activities aid our customers in speeding up their assembly line performance and part identification.

In this application, (Picture on left), 2 ‘U-nut” style thread keepers are installed in specific locations after molding and an identifying sticker which contains the customers SKU number and a barcode that is scanned to quickly identify the part on the assembly line. |

Secondary Operations

In conjunction with value added operations, other secondary operations are performed by Foxboro to make parts easier to use in assembling the final product or prepare the part for sale. Some of the secondary operations Foxboro currently performs for its customers are; assembly, hot stamping, riveting, stapling, labeling, and retail packaging. |

Specialized Packaging Requirements

As custom computerized inventory systems are becoming more popular and widely used, the packaging of manufactured goods is also becoming more important. Foxboro has worked with many of our customers to incorporate specialized packaging requirements into the manufacturing process. We can accommodate size, weight, and/or quantity requirements on pallets of finished goods as dictated by your inventory kanban system or produce and install barcodes for inventory identification. We can also arrange for our corrugation suppliers to produce custom sized and custom labeled containers for your unique product. |

In one application our customer primarily sells their product through catalogue orders with a kanban inventory system in quantities of 12. With the assistance of our corrugation supplier we developed a dual purpose packaging system that first allows us to send product to our customer in quantities of 12 and then secondly allows our customer to quickly take the individually packaged product and send it out in the mail to satisfy their catalogue orders without having to repackage the product, (Picture on right). |

Similarly, another customer has a weight restriction on their packaged inventory for their assembly line, we worked with our customer and corrugation supplier to develop packaging to fit within the weight restrictions and maximize assembly line efficiency with the use of cell partitions, (Picture on left). |